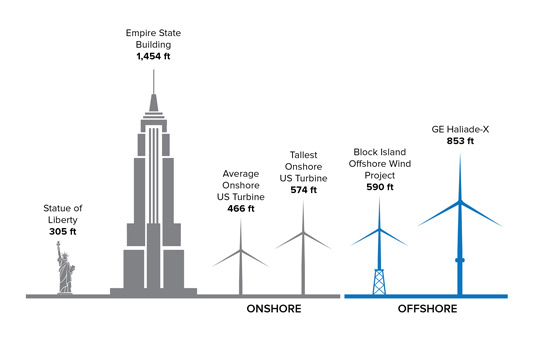

New Jersey’s wind farms are going to be big, but the actual turbines are huge, dwarfing the Statue of Liberty by nearly three times. According to Governor Phil Murphy, the New Jersey shoreline is going to be a non-stop horizon of these things. Hundreds of these massive structures will be visible from the shoreline.

New Jersey’s Paulsboro Marine Terminal is quickly becoming the epicenter for offshore wind construction in the U.S., and it’s not playing small. This facility is home to EEW American Offshore Structures, where they are manufacturing the massive steel monopiles that will serve as the foundation for future offshore wind turbines. These monopiles are enormous—up to 400 feet long and weighing as much as 5 million pounds. Once fully operational, the plant is expected to produce around 100 monopiles annually, supporting multiple wind projects along the East Coast.

But what’s truly mind-blowing is just how big the wind turbines themselves are. Offshore turbines like the GE Haliade-X (which will be used for New Jersey’s Ocean Wind 1 project) are some of the tallest structures on the planet, reaching heights of over 850 feet—nearly three times the size of the Statue of Liberty. Each blade is the length of a football field, and these giants can generate up to 12 megawatts of power per turbine.

Constructing these behemoths is no easy task. Driving a monopile into the ocean floor takes serious effort. These steel cylinders, typically up to 12 meters in diameter, need to be hammered 150 feet deep to provide the sturdy base needed to support the enormous turbines. Specialized jack-up vessels are used to transport and install the structures in the often-challenging marine environment.

However, this massive green energy push comes with a critical question: Is it truly “green”? The production of steel monopiles and blades, along with the installation process, requires large amounts of raw materials and energy—much of which still comes from fossil fuels. There’s also the environmental impact of transporting and erecting these structures. While offshore wind farms are designed to reduce carbon emissions long-term, the initial footprint of building and deploying these projects is significant.

EEW American Offshore Structures (EEW AOS) is a game-changing force in the U.S. offshore wind industry, and its facility in Paulsboro, New Jersey, is central to this transformation. EEW AOS is the American subsidiary of Germany’s EEW Group, one of the world’s leading manufacturers of steel monopiles—the enormous foundation structures needed for offshore wind turbines.

Founded in 1936, EEW has a long history of manufacturing steel tubes for various industries, but it’s their expertise in large-diameter steel components that has made them a key player in the offshore wind sector. The Paulsboro facility, which began production in 2021, is their first major U.S. venture. The project was born from New Jersey’s aggressive push into renewable energy, backed by a $250 million investment from the state.

EEW AOS specializes in the production of monopiles, the critical foundation structures that are driven into the seabed to anchor wind turbines. These monopiles are some of the largest steel structures ever made for renewable energy—up to 40 feet in diameter, 400 feet long, and weighing as much as 5 million pounds. To put that in perspective, each monopile is comparable in size and weight to a Saturn V rocket.

The Paulsboro facility’s strategic location on the Delaware River gives it easy access to East Coast offshore wind projects. From here, EEW AOS plans to produce over 100 monopiles per year at full capacity, employing more than 500 workers by the time the facility is fully operational by 2026.

This production will support projects like Ocean Wind 1 and Atlantic Shores, which are key to New Jersey’s offshore wind goals of generating 7,500 megawatts of wind energy by 2035.

EEW’s Paulsboro plant is a crucial part of the growing U.S. offshore wind supply chain, marking the first step toward domestically produced wind energy infrastructure. Before this, monopiles had to be imported from Europe, leading to higher costs and longer lead times. By localizing production, EEW is not only making offshore wind more accessible but also creating hundreds of jobs in the region.

In essence, EEW’s work in Paulsboro is an anchor for the future of renewable energy in the U.S., laying the groundwork—literally—for cleaner, greener energy.

In short, New Jersey is diving headfirst into the future of clean energy, but the debate over the environmental cost of such enormous infrastructure still rages.